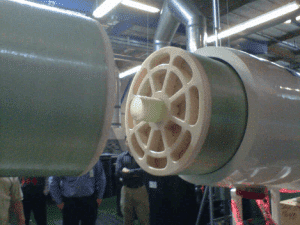

Injection Molding

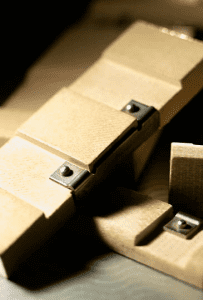

Along with our injection molding presses ranging from 35 to 200 tons, we also bring to the table strong domestic and foreign partnerships for mold creation and the ability to work with a 3D-printed mold to prove our designs along the way.

Not sure what you need?

We are here for you. Based on our extensive knowledge of industry standards and best practices, we will act as your trusted design partners and solution providers.

At Spaulding Composites we will:

- Be a partner from the prototype phase to production and post-production order fulfillment.

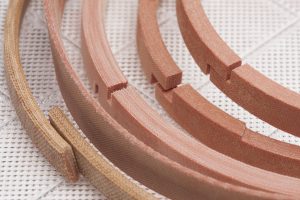

- Provide you with process and materials experts to assist with designing special parts and optimizing your design for injection molding.

- Work with you to determine which material best suits your needs, unlocking the true potential of your design.

- Evaluate the number of actions or molds needed, providing critical feedback to simplify the molds or design while keeping design needs at the forefront.

- Deliver high-quality parts and finishes, at high production speeds and volumes.

- Provide in-house secondary processes like Precision CNC Machining, Assembly, Kitting & Packaging, Marking, Hot Stamping, and Over-Molding.

Our partners choose us for the complex molded products we deliver, our proven full-service partnership, and the in-depth knowledge and support from our top engineers throughout the entire process.

Related Markets

Spaulding Composites, Inc is a manufacturer and fabricator of engineered thermoset advanced composite materials and components, designed to meet and exceed the specific requirements of our global industrial customers.

Why Choose Us?

If you’re looking for high-performance injection molding solutions contact Spaulding Composites today. We are a global supplier of specialized composite materials and value-added fabrication solutions.

Related Applications

In order to succeed, your company needs a reliable partner for your high technology products.

Contact the Leaders in Engineered Composites

We would love to hear from you! Have a question, or simply interested in learning more about our engineered composites and materials? Please fill out the easy contact form below and one of Spaulding’s representatives will contact you soon. Thank you!