Advancements and Market Dynamics of Filament Wound Bearings in the Engineered Composite Materials Industry

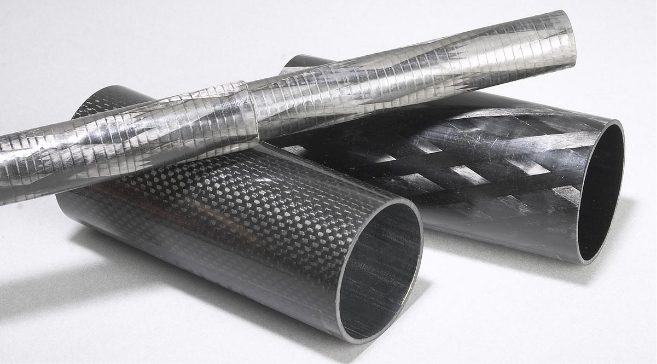

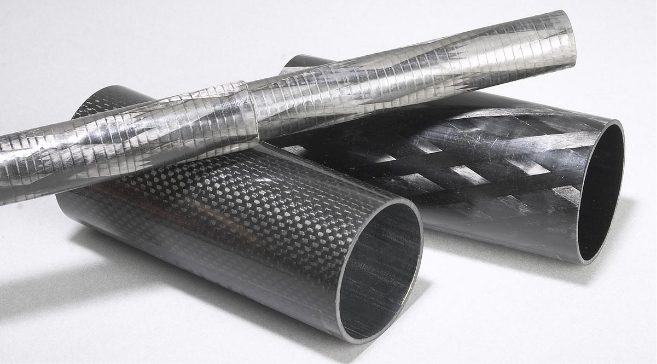

Developed in the mid-20th century, filament winding makes composite structures by winding reinforced fibers impregnated wit…

Learn More >

Developed in the mid-20th century, filament winding makes composite structures by winding reinforced fibers impregnated wit…

Learn More >

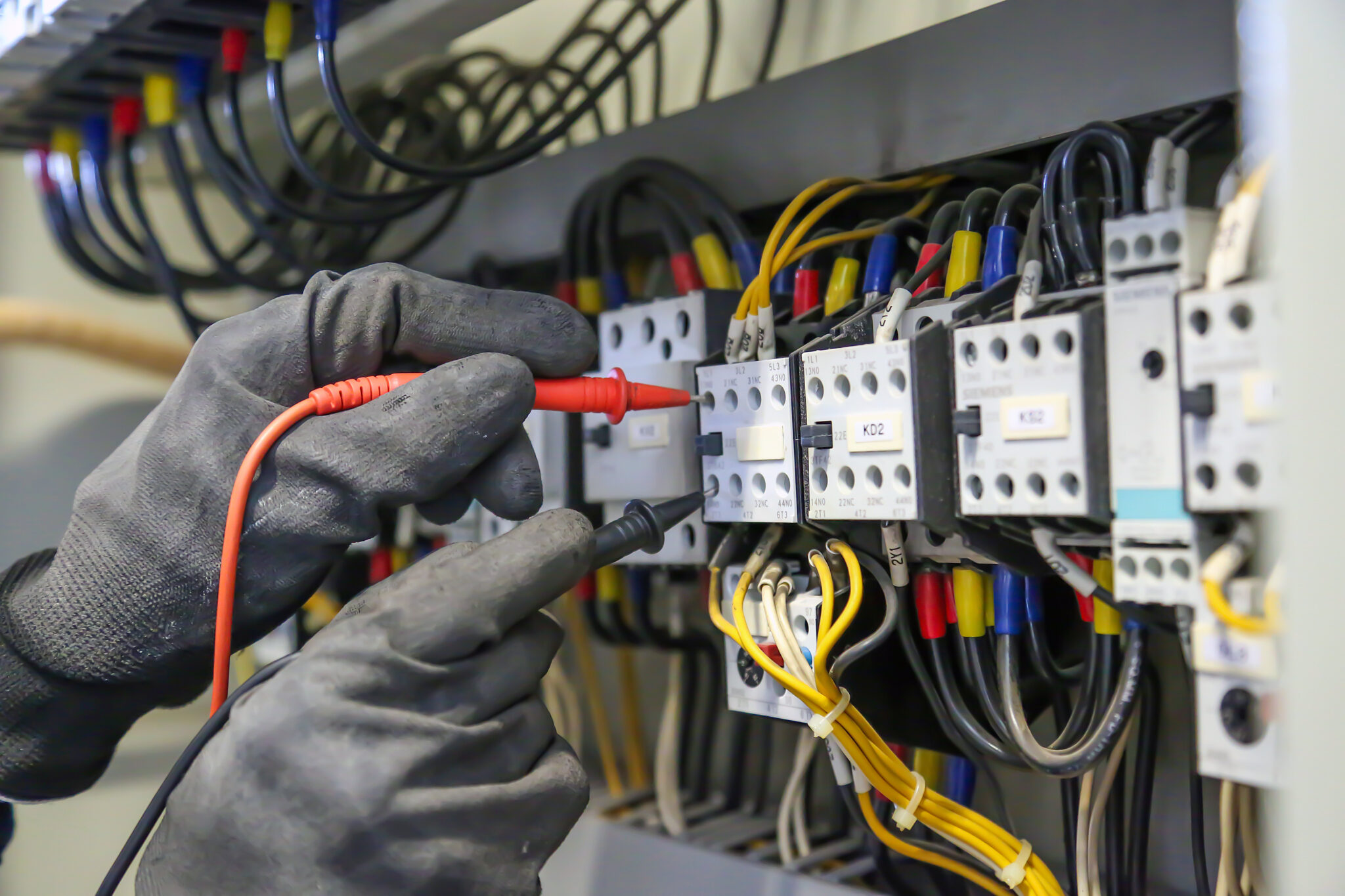

Tools that work pneumatically have numerous components, with vanes being a particularly important part of many motors that p…

Learn More >

A laminated thermoset composite that consists of a matrix made from epoxy resin and woven glass cloth was first introduced i…

Learn More >

Many manufacturers prefer machining over molding for various plastic parts and products.

Learn More >

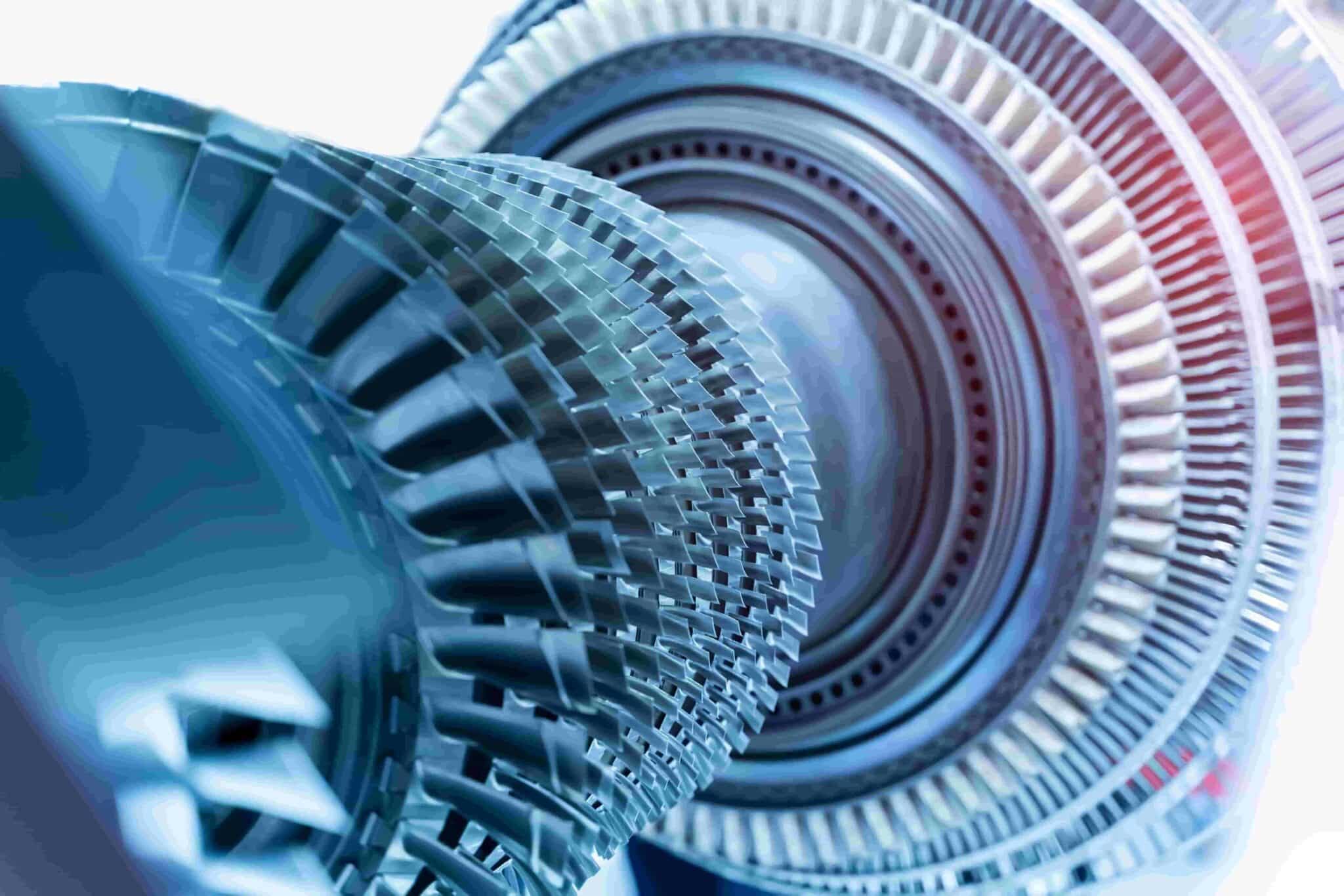

A bearing helps reduce friction between machine parts for easier movement. It guides and supports machine parts in transferr…

Learn More >

The materials that work best for cryogenic systems and parts depend largely on the application, operating conditions, and sy…

Learn More >

Explore the world of machined plastics and their applications in various industries.

Learn More >

Explore the world of cryogenic systems and their essential components like dewars, neck tubes, and transfer hoses.

Learn More >

Learn about the properties and applications of G10-CR composites for cryogenic materials and neck tubes.

Learn More >

Discover how Spaulding Composites can assist with metal-to-plastic conversions.

Learn More >