Sliding Vane Pumps

Some examples of fluids they are commonly used to transfer are:

- Lubricants

- Lighter petroleum-based fluids

- Propane

- Alcohols and other chemicals

- Liquefied gases

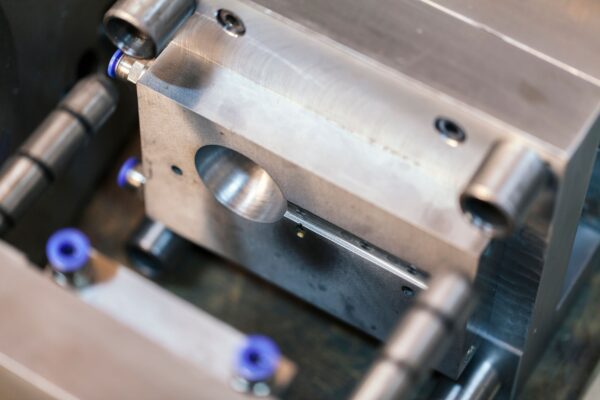

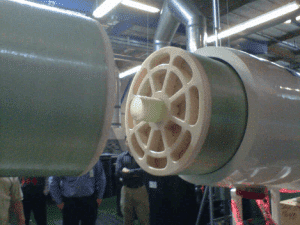

Sliding Vane Pumps work by spinning a metal rotor inside an asymmetrical chamber. The rotor is powered externally and has precision cut slots running axially along the length of the rotor. Inside these slots sit composite vanes. As the rotor turns, the vanes move in and out of the slot to maintain contact with the inner wall of the chamber.

As the vanes spin towards the entry point of the fluid into the chamber, the vanes extend out, capture, and push the fluid through. The fluid exits the chamber on roughly the opposite side of the entry. As the vanes rotate past the exit point, they slide back into the slot on the rotor.

Vane selection is a critical part of optimizing pump functionality. One of the most important aspects is that the vanes are not metal, so as to reduce friction and allow the pump to operate with corrosive fluids. With our wide variety of materials and engineering expertise, Spaulding Composites can design and manufacture vanes to fit your application.

Whether it’s our aramids or glass substrates and our phenolic or epoxy resins, we have the knowledge and ability to make your designs successful in any environment. We can also add features and components, such as metal retaining clips and pins, to give your vanes added functionality and robustness.

Call us today. Let us show you how we can help make your pumps the best on the market.

Related Markets

Spaulding Composites, Inc is a manufacturer and fabricator of engineered thermoset advanced composite materials and components, designed to meet and exceed the specific requirements of our global industrial customers.

Contact the Leaders in Engineered Composites

We would love to hear from you! Have a question, or simply interested in learning more about our engineered composites and materials? Please fill out the easy contact form below and one of Spaulding’s representatives will contact you soon. Thank you!