Capabilities

To maximize your design and product’s potential, you need a partner with a breadth of capabilities that can support you from the time you start a design effort for your customer until your products go into production.

Spaulding Composites is that partner. We provide the experience and knowledge to add value to our partners in any stage of their process, from new product development and prototyping, through production support at any volume. We have the breadth of capabilities and depth of experience to be a part of your team, regardless of where you are in your product life cycle.

Call Spaulding Composites today. You’re not just buying a product. You’re buying the safety and security of knowing that your application will function as needed because you trusted Spaulding’s capabilities throughout the development cycle. Let us put our manufacturing and materials expertise to work for you!

Injection Molding

We have been injection molding for 40+ years, serving markets as straightforward as consumer products to mission-critical, high-complexity arenas like serving the military and medical devices.

Learn More >

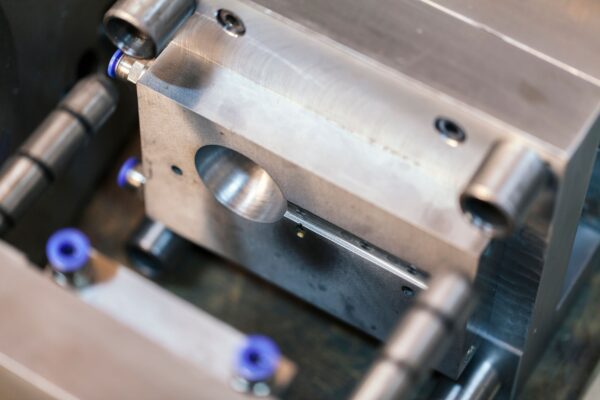

Tooling

Success in manufacturing is a multi-step approach, and every supplier understands how critical the part design phase is.

Learn More >

CNC Machining

World-class businesses require world-class suppliers. World-class suppliers are flexible partners with the ability to support their customers through a variety of needs.

Learn More >

Convolute Wound Tubes

Spaulding Composites can manufacture convolute wound tubes up to 48 inches in length. Our inner diameters can be wound as small as 0.125 inches for fabrics/0.250 inches for G10 and G11. Our outer diameters can be wound up to 18 inches.

Learn More >

Filament Wound Tubes

Filament Winding is one of the oldest composite manufacturing processes yet is still widely used to create complex, lightweight structures designed to provide strong mechanical properties in specific applications.

Learn More >

Engineering Support

Designing products made from composites and plastics can be a daunting task. While the materials seem straightforward in their properties and performance, there is a great deal of nuance and specific knowledge required to manufacture parts to meet the desired application.

Learn More >