Electrical Insulation

However, using electricity for a variety of applications, such as lamps, streetcars, and industrial motors, was complicated as transformer technology had not yet been invented. Every application needing electricity had to have its own generator and its own transmission lines to provide the specified voltage.

Shortly thereafter, dozens of scientists and engineers throughout the United States and Europe rushed to solve the long-distance transmission. The design that became the blueprint for modern transmission using step-up and step-down transformers was developed in 1886 by Westinghouse, Stanely, and Pope in Massachusetts. Since then, the use of electricity for everything from desk lamps to industrial HVAC systems to charging electric vehicles has exploded.

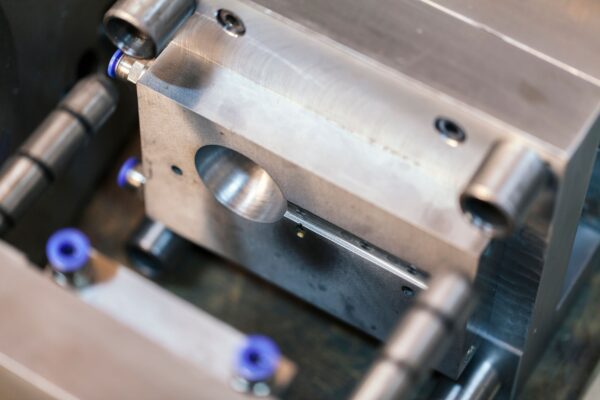

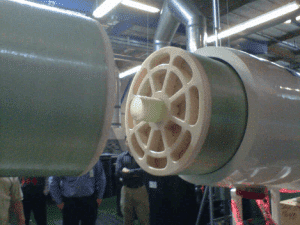

Transmission and distribution of electricity is a core industrial need of any functioning economy around the world. This technology requires specialty materials to provide insulators, fuse tube bodies, and handling tools. Faulty materials and designs can be disastrous. Spaulding Composites has the experience and design knowledge to provide the expertise you look for in the development stage and the reliability and high quality you need in the manufacturing phase. Our high-quality papers and cottons provide consistent dielectric properties for your insulators. Our tough glass epoxies provide the safety needed for fuse tube bodies and utility tools. Our decades of manufacturing and machining experience using these materials make us the premier choice for bringing your products to light!

Our experienced engineers can provide in process dielectric testing so you know your insulators will function as needed when installed. Our manufacturing team can also install supplemental components to provide near finished products for your fuse tubes and tools.

Call Spaulding Composites today. Let us show you how we can provide the engineering expertise to make sure your products function as needed with the safety you require.

Related Markets

Spaulding Composites, Inc is a manufacturer and fabricator of engineered thermoset advanced composite materials and components, designed to meet and exceed the specific requirements of our global industrial customers.

Contact the Leaders in Engineered Composites

We would love to hear from you! Have a question, or simply interested in learning more about our engineered composites and materials? Please fill out the easy contact form below and one of Spaulding’s representatives will contact you soon. Thank you!