Air Tools

While the designs are straightforward, they are critical for many industries to function properly. Every day, millions of mechanics rely on air tools to keep cars moving and America’s workforce commuting. Our military uses these tools to keep their vehicles working and help protect our country. Precision torque tools are used in mission critical assemblies such as power plants, aircraft, and spacefaring vehicles. Pneumatic tools literally help keep the population progressing forward.

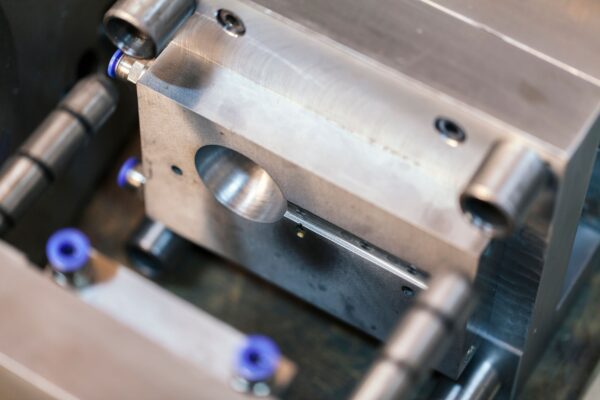

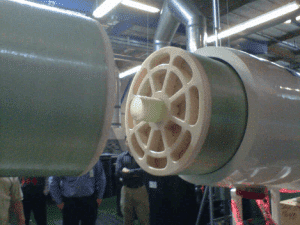

Pneumatic tools work by harnessing compressed air into the tool to spin a metal rotor at high torque rates. The metal rotor has precision slots machined into the outer diameter running axially along the length. Inside these slots are composite vanes (sometimes called blades). These vanes slide in and out of the slot as the rotor turns. They extend as they rotate towards the air source to catch the compressed air and spin the rotor. As the rotor rotates away from the source, the vanes retract into the slot. It is imperative that these vanes are made from materials that resist heat from friction and have some capacity for retaining oil and having some self-lubricity.

Spaulding Composites has been providing vanes for the pneumatic tool market for over 40 years. Our custom composites are used by the biggest names in air tools due to their quality, reliability, and mechanical characteristics. Our highly trained engineers and operators can manufacture incredibly tight tolerances and complex shapes in high volumes. Not only will our vanes give your tools an edge, but our manufacturing capabilities will also ensure you will have vanes when you need them.

Contact Spaulding Composites. Let our skills and experience benefit your tools.

Related Markets

Spaulding Composites, Inc is a manufacturer and fabricator of engineered thermoset advanced composite materials and components, designed to meet and exceed the specific requirements of our global industrial customers.

Contact the Leaders in Engineered Composites

We would love to hear from you! Have a question, or simply interested in learning more about our engineered composites and materials? Please fill out the easy contact form below and one of Spaulding’s representatives will contact you soon. Thank you!