Convolute Wound Tubes

Convolute Wound Tubes at Spaulding Composites, Inc

Convolute wound tubing involves taking a resin-impregnated fabric and wrapping it around a precision ground, plated steel mandrel under heat and pressure. The wrapped mandrel is then cured over a certain time period at a specific temperature.

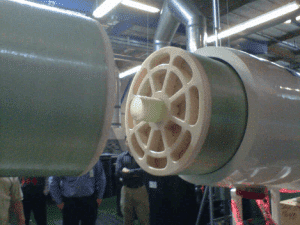

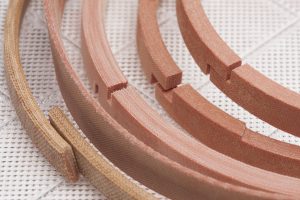

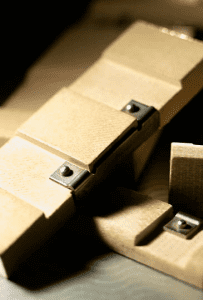

Once the cure cycle completes, the composite tube is removed from the mandrel. This composite tube provides the base shape for cylindrical and tubular shaped products for a wide variety of industries.

Cotton phenolic tubes can be machined into bushings and bearings for heavy industrial equipment, such as axle-pinion bearings in front-end loaders and tandem axle articulation pivots in road graders. Certain grades can be machined into electrical insulators with very good dielectric properties and flexural strengths, while another class of materials can be made into artificial lift components for oil and gas completions.

Related Markets

Spaulding Composites, Inc is a manufacturer and fabricator of engineered thermoset advanced composite materials and components, designed to meet and exceed the specific requirements of our global industrial customers.

We Meet and Exceed Your Requirements

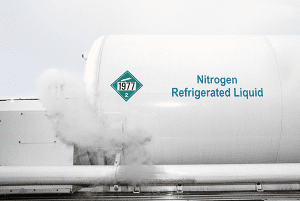

Certain glass epoxy tubes can be precision machined into neck tubes for cryogenic storage Dewars. Other grades leverage their high mechanical strength to be made into tank spacers for cryo bulk storage of industrial gasses. Still, others are made into components for utility-grade, electrical grid parts.

Spaulding Composites can manufacture convolute wound tubes up to 48 inches in length. Our inner diameters can be wound as small as 0.125 inches for fabrics/0.250 inches for G10 and G11. Our outer diameters can be wound up to 18 inches. We can build wall thicknesses up to 1.5 inches for fabrics and 1 inch for G10/G11. This gives us a large work envelope within which to build the parts you need to make your systems better.

Reach out to us, and see how we can help!

Related Applications

In order to succeed, your company needs a reliable partner for your high-technology products.

Contact the Leaders in Engineered Composites

We would love to hear from you! Have a question, or simply interested in learning more about our engineered composites and materials? Please fill out the easy contact form below and one of Spaulding’s representatives will contact you soon. Thank you!