Water Purification

More and more intensely dry weather systems combined with increased consumption of water stemming from an increased population are driving us to look for alternative solutions for water.

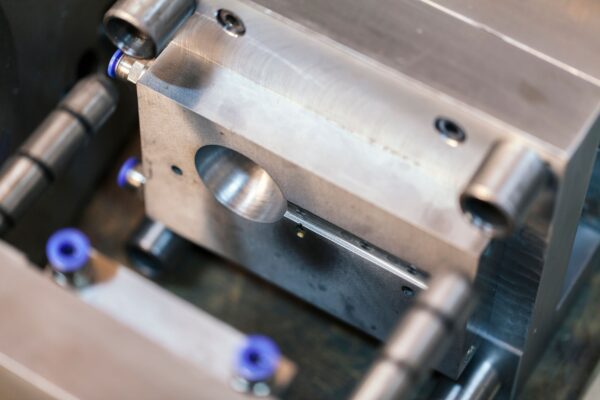

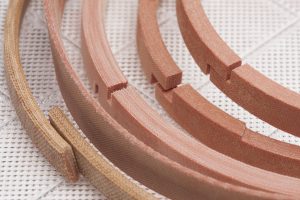

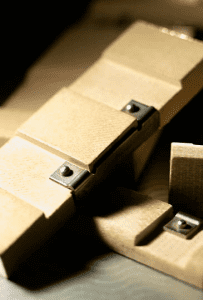

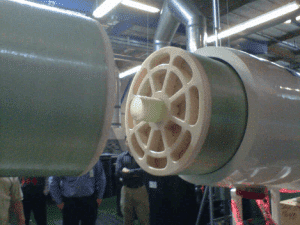

Spaulding Composites glass epoxy systems are a key component of those solutions. Reverse osmosis water purification is the process of using very high pressures to force contaminated water and fluids through a semipermeable membrane. This membrane filters out the contaminants on one side and allows for clean drinking water to flow through to the other side. For this process to work, the outer tube containing the membrane must be incredibly strong and resistant to water, molds and other contaminants. Spaulding Composites filament wound tubes meet or exceed the mechanical requirements necessary to support this process. We can also injection mold the interconnectors to reduce the number of suppliers you need to work with.

Reach out to us today. Ask us how our engineers can help you design core tubes and interconnectors to meet your requirements. And then see how our manufacturing teams can supply you with the products you need exactly when you need it. We understand the unique demands of large filtration system installations at the outset combined with the need to provide spare parts throughout the life of the system. Let us help you design your parts and your service plans to meet your business needs.

Related Applications

In order to succeed, your company needs a reliable partner for your high-technology products.

Contact the Leaders in Engineered Composites

We would love to hear from you! Have a question, or simply interested in learning more about our engineered composites and materials? Please fill out the easy contact form below and one of Spaulding’s representatives will contact you soon. Thank you!